The metal ore will be evenly conveyed by vibrating feeder to jaw crusher for primary crushing, the crushed material will be conveyed by belt conveyor to cone crusher for further crushing, material after being crushed will be conveyed to vibrating screen for screening, and material with qualified particle size will be conveyed by belt conveyor to product pile; material with unqualified particle size will be back from vibrating screen to cone crusher for secondary and tertiary crushing, to achieve a closed circuit. Particle size of product can be combined and graded according to the requirement of client.

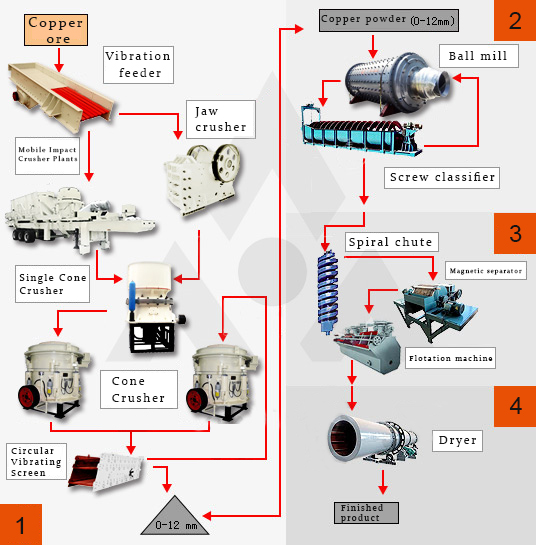

PROCESSING TECHNOLOGY: Copper ore processing production process include: crushing, grinding, ore dressing three processes. Crushing process, the three sections of the closed-circuit is the copper ore crushing, to complete the ore crushing and partial dissociation of the work, thereby improving the follow-up grinding efficiency; grinding process, two-stage closed grinding efficient grinding process, you can make the copper mill more fully.

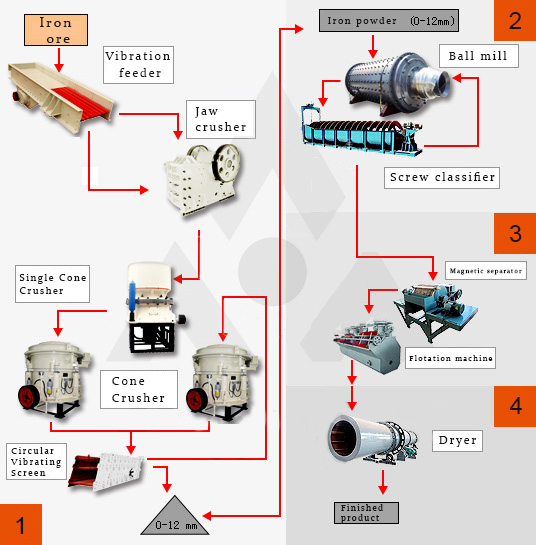

PROCESSING TECHNOLOGY: According to the category and characteristic of ore, there are many different processes for iron ore dressing. In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing iron ore. Jaw crusher is usually used for primary crushing; cone crusher is used for secondary and tertiary crushing. Through primary crushing, and then by secondary and tertiary crushing, ore will be crushed to the suitable size for feeding ball mill.

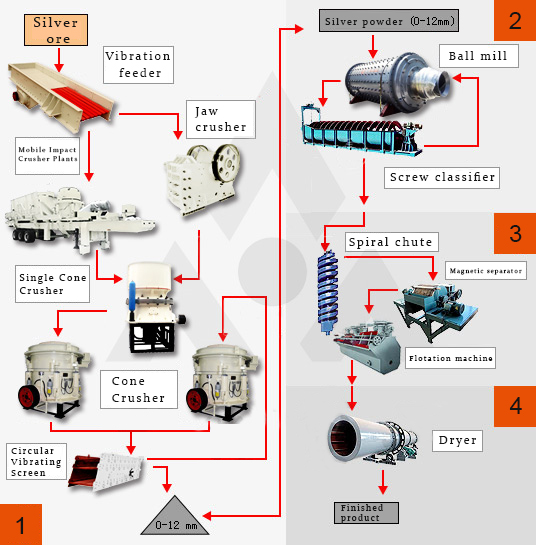

PROCESSING TECHNOLOGY: Silver is commonly extracted from ore by smelting or chemical leaching. Silver involved in mixing silver ore, salt, copper sulphide, and water.

Leave your needs, Our sales manager will contact with you as soon as possible.

TEL:0086-371-67660555

E-mail:sales@zxcrusher.com

Whatsapp/Wechat:+86-13676922906

Chinese website:www.jzzxzg.com

English website:www.zxcrusher.com

España:www.zxcrusher.es Русский:www.zxcrusher.ru