Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA. Jaw Crusher is of high crushing ratio, large capacity, well-distributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc. It is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

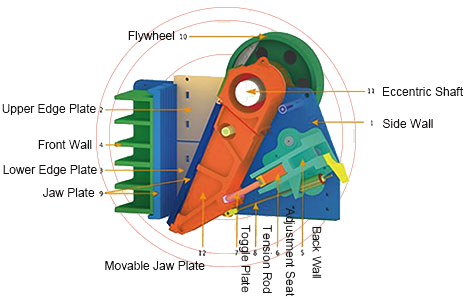

Jaw Crusher Working Principle The electrical motor transmits power to the eccentric shaft through v-belt and belt pulley. Then the exciting force generated by the eccentric shaft will make the movable jaw move upwards and downwards. This movement would trigger the toggle plate to push the movable jaw forwards and backwards. When the movable jaw moves forth towards the fixed jaw, materials in the crushing cavity will be squashed or chopped. And then the movable jaw travels back, the chopped or squashed materials which meet the requirement will be discharged from the outlet. Since the motor keeps working.

| Model | Feeding size(mm) | Max feeding size(mm) | Discharging Range size(mm) | Capacity (t/h) | Motor power(kw) | Weight (t) |

| PE-250*400 | 250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.5 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 10.6 |

| PE-600*900 | 600*900 | 500 | 65-180 | 80-180 | 55-75 | 15.5 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 90-110 | 28 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 90-110 | 30 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 90-110 | 30.5 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 90-110 | 31 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 110-132 | 49 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 110-132 | 51 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160 | 100.9 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 22 | 4.9 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30-37 | 6.5 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37 | 7.7 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 75 | 11 |

Raw material:River Stone

Capacity:250 t/h

Max feeding size:630mm

Equipment Configuration of River Stone Crushing Plant: 1set ZSW490*110 Vibrating Feeder + 1set PE750*1060 Jaw Crusher + 1sets XHP300 Hydraulic Cone Crusher + 1set 3YK2470 Vibrating Screen + 1set B1000×15mBelt conveyor +1set B1000×18mBelt conveyor +1set B1000×25mBelt conveyor +1set B800×32mBelt conveyor +1set B500×15mBelt conveyor + Electronic control system

Design Description:In the plant, raw river stone will probably be fed into jaw crusher for primary crushing by vibrating feeder. After primary crushing, the material will probably be transferred to secondary crushing equipment like hydraulic cone crusher for further crushing.

Raw material:Granite

Capacity:300-350 t/h

Max feeding size:800mm

Equipment Configuration of Granite Crushing Plant:ZSW600x130 vibrating feeder+ PE900x1200 jaw crusher+ XHP300x 2sets hydraulic cone crusher+ belt conveyor+ 3YK2460x2sets circular vibrating screen

Design Description: This is a stationary three-stages crushing plant . The design capacity is 300-350t/h, with the function of crushing, screening and reshaping.

Leave your needs, Our sales manager will contact with you as soon as possible.

TEL:0086-371-67660555

E-mail:sales@zxcrusher.com

Whatsapp/Wechat:+86-13676922906

Chinese website:www.jzzxzg.com

English website:www.zxcrusher.com

España:www.zxcrusher.es Русский:www.zxcrusher.ru