XHP Series Hydraulic Cone Crusher not only improves the production capacity and crushing efficiency, but also widens the applying area, from limestone to basalt, from stone production to various ore crushing.

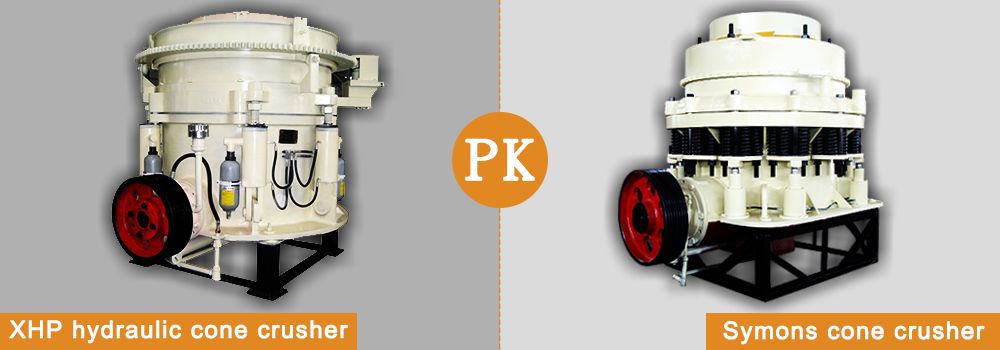

It has crushing performance in the work of medium-size crushing, fine crushing. The crusher is the improved type of spring cone crusher and can be used to replace ordinary hydraulic cone crusher .

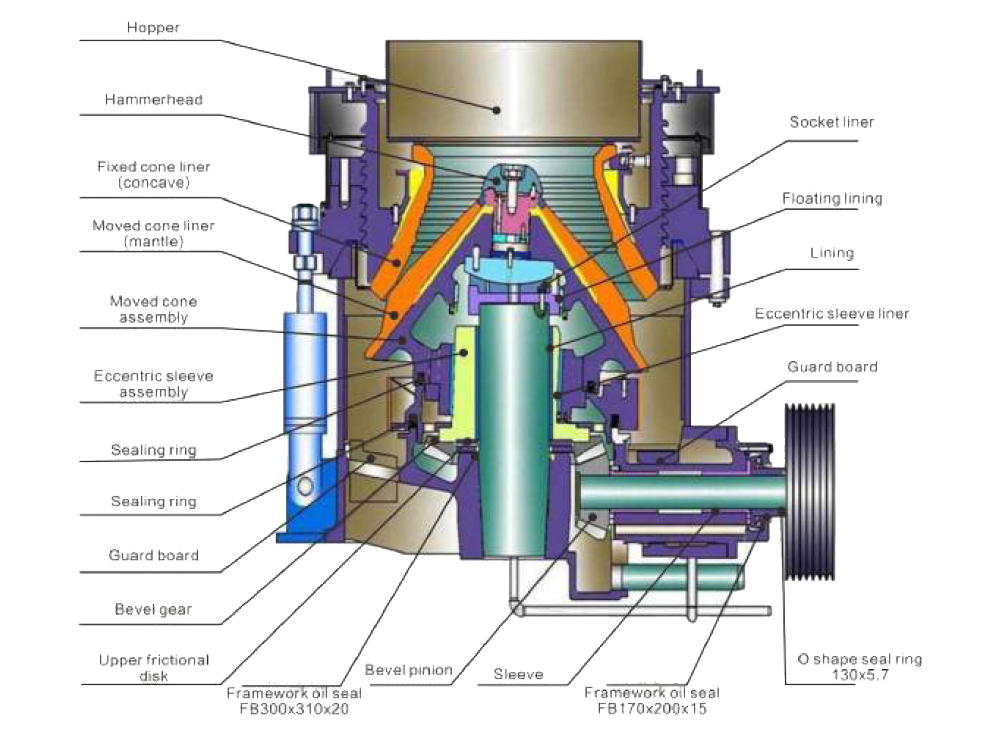

In PSG Series Compound Cone Crusher, the rotating forces of movable cone and eccentric shaft are at different sides of machine central line, while in multi-cylinder hydraulic cone crusher, the forces are at same side. In this way, the rotating speed increases about 50% than the same specification PSG Series Compound Cone Crusher. because the rotating speed of eccentric shaft increase, and the movable cone rotate speed also increase, thus the times of stone being crushed in cavity increase, which makes it possible to get laminate crushing. Percentage of fine material becomes more and the grade is more even, and more cubic aggregate.

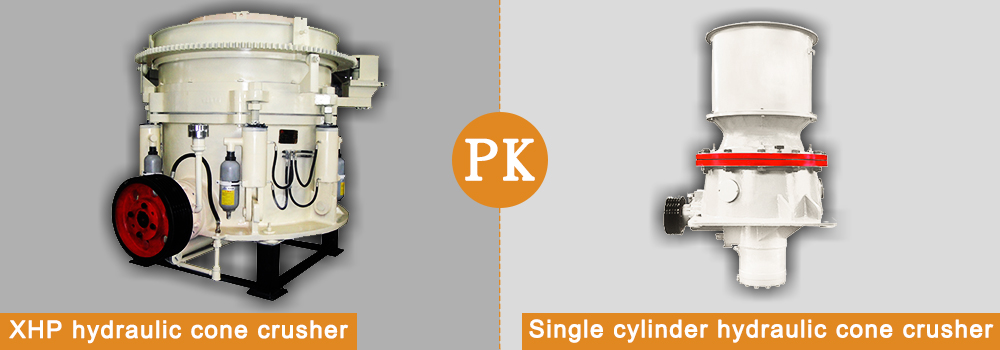

Mantle’s angle of single cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusherr is same, so, the time which material detains in cavity is almost same. So, the faster of rotating speed, the better laminate crushing.result due to the swing speed of multi-cylinder is much faster than single cylinder meanwhile they have some same features.

Due to the limitation of backup parts structure, the crushing cone stroke of single cylinder cone crusher is much smaller than multi-cylinder, so the crushing result has much difference.

| Types of Cone Crusher | Advantages | Disadvantages | Applications |

| Spring Cone Crusher | The cheap of all types | Poor sealing reliability; Lower manufacturing precision; Operational reliability is lower than PSG Series Compound Cone Crusher; Low production capacity; Less product fineness and more flaky shape than HP cone crusher. |

Less initial investment, less demanding on the crushed product fineness or shape. |

| PSG Series Compound Cone Crusher | Reliable operation,Sealed with a dry oil. | Less product fineness and more flaky shape than HP cone crusher. | Requirements on the product fineness and shape between spring cone crusher and HP cone crusher . |

| XHP Series Multi-cylinder Hydraulic Cone Crusher |

High production capacity, fine size and cubic shape. In the mining industry, ideal of “more crushing and less grinding” can be realized, reducing production cost in mining industry. |

Speed of mental is high, which needs more careful operation and maintenance. | High requirements on production capacity and crushing particle size and shape. |

| Single Cylinder Hydraulic Cone Crusher | High production capacity, simple structure, reliable operation | Product size is not as fine as HP, not as good shape as XHP | Suitable as secondary crushing |

| Jaw Crusher | Simple structure Cheap price | Low production capacity. The product size is not fine enough, flakiness stone occupy a high proportion | Suitable for primary crushing |

| Impact Crusher | Simple structure, cheap price Product shape is fine and cubic | Too much dust in production; high frequency of hammer changing,operational efficiency is low and high production costs | Production of high grade aggregate for high-way. |

XHP series hydraulic cone crusher can be widely used for highway pavement material,sand and gravel aggregate for high speed passenger railway line, hydropower station, such as limestone, granite, gabbro, basalt, river stone, coal gangue, quartz, diabase, iron ore, copper ore, zinc ore, manganese ore, etc. Next, let's see production sites of XHP hydraulic cone crusher.

Material: Mountain stone

Feeding size: 1200mm

Final size: 10, 20,30,50mm

Capacity: 1000t/h

Configuration: ZSW600x200 vibrating feeder+ PE1500x1800 jaw crusher+ XHP500x 2sets hydraulic cone crusher+ 8sets belt conveyor+ 4YK2470x4sets circular vibrating screen

The advantage of this line is: XHP500 hydraulic cone crusher, its crushing performance make customer save the cost and the crushing line makes the customers get more cubic shape material.

Material:Aggregate stone

Feeding size:650mm

Final size: 3, 6, 10, 26, 40mm

Capacity:200t/h

Configuration:ZSW490x110 vibrating feeder+ PE750x1060 jaw crusher+ XHP300 hydraulic cone crusher+ 4sets belt conveyor+ 2YK2160 circular vibrating screen+ 3YK2160 circular vibrating screen

The advange of this line is: XHP300 hydraulic cone crusher, its crushing performance make customer save the cost and the crushing line makes the customers get more cubic shape material.

Material:Granite

Feeding size:800mm

Final size:0-5, 5-12,12-21mm

Capacity:350t/h

Configuration: ZSW600x130 vibrating feeder+ PE900x1200 jaw crusher+ XHP300x 2sets hydraulic cone crusher+ belt conveyor+ 3YK2460x2sets circular vibrating screen

This is a stationary three-stages crushing plant . The design capacity is 300-350t/h, with the function of crushing, screening and reshaping.

Leave your needs, Our sales manager will contact with you as soon as possible.

TEL:0086-371-67660555

E-mail:[email protected]

Whatsapp/Wechat:+86-13676922906

Chinese website:www.jzzxzg.com

English website:www.zxcrusher.com

España:www.zxcrusher.es Русский:www.zxcrusher.ru