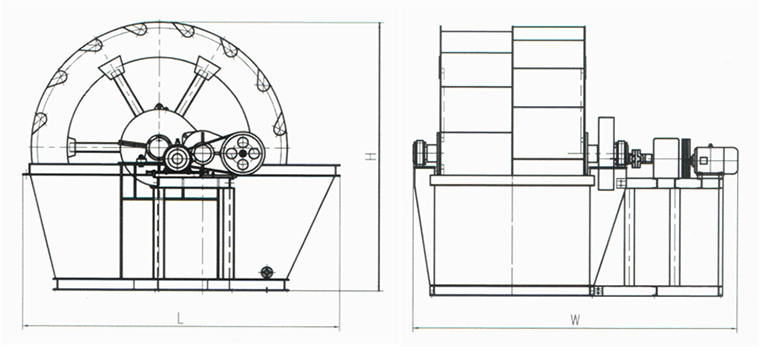

Sand Washing Machine

- Type:Necessary Auxiliary Equipment

- Input Size:≦10 mm

- Processed Materials:Limestone, River Gravel, Granite, Basalt, Quartz, Iron Ore, Diabase etc.

- Applications:Sand Washing, Aggregate Field, Concrete Mixing Plant, Dry Mortar Plant Desulfurization, Quartz Sand etc.

- Capacity:20--180THP

Specifications:

| Model | Bucket wheel diameter (mm) |

Max feeding size (mm) |

Capacity (t/h) |

Speed (r/min) |

Power (kw) |

Overall dimension (L×W×H)(mm) |

Weight (t) |

|

|

2600 |

≤10 |

20-50 |

2.5 |

5.5 |

3550X2080X2650 |

2.67 |

|

|

2600 |

≤10 |

30-70 |

2.5 |

5.5 |

3550X2080X2650 |

2.9 |

|

|

2800 |

≦10 |

50-100 |

1.2 |

11 |

39641x21371x2895 |

3.98 |

|

XS3200 |

3200 |

≤10 |

80-120 |

1.2 |

15 |

4346x2934x3345 |

7.27 |

|

XS3600 |

3600 |

≤10 |

120-180 |

1 |

15 |

4355X4505X3810 |

9.43 |

- Diameter (mm):610-1500

- Slot length(mm):7225-10300

- Capacity (t/h):40-200

- Feeding Size(mm):≦10

- Water Consumption:6-160

Specifications:

|

Model |

Screw diameter(mm) |

Length of Chute (mm) |

Max feeding size(mm) |

Capacity (t/h) |

Speed (r/min) |

Power (kw) |

Water Consumption(t/h) |

Overall dimension(L×W×H)(mm) |

Weight(t) |

|

XL508 |

508 |

6705 |

≦10 |

20 |

38 |

5.5 |

6-60 |

8000*2343*1430 |

2.67 |

|

XL610 |

610 |

7225 |

≦10 |

40-50 |

32 |

7.5 |

6-63 |

8000*2050*1400 |

3.80 |

|

XL762 |

762 |

7620 |

≦10 |

50-75 |

26 |

11 |

9-63 |

8545*2650*3862 |

5.23 |

|

XL920 |

920 |

8026 |

≦10 |

100 |

18 |

11 |

10-80 |

8715X1632X2075 |

4.6 |

|

2XL920 |

920 |

8026 |

≦10 |

150-180 |

18 |

2*11 |

20-160 |

8715X2602X2075 |

7.9 |

|

XL1115 |

1115 |

8532 |

≦10 |

175 |

18 |

15 |

20-150 |

9231X1833X2126 |

5.6 |

|

2XL1115 |

1115 |

8532 |

≦10 |

200-250 |

18 |

2*15 |

40-300 |

9231X2995X2126 |

10 |

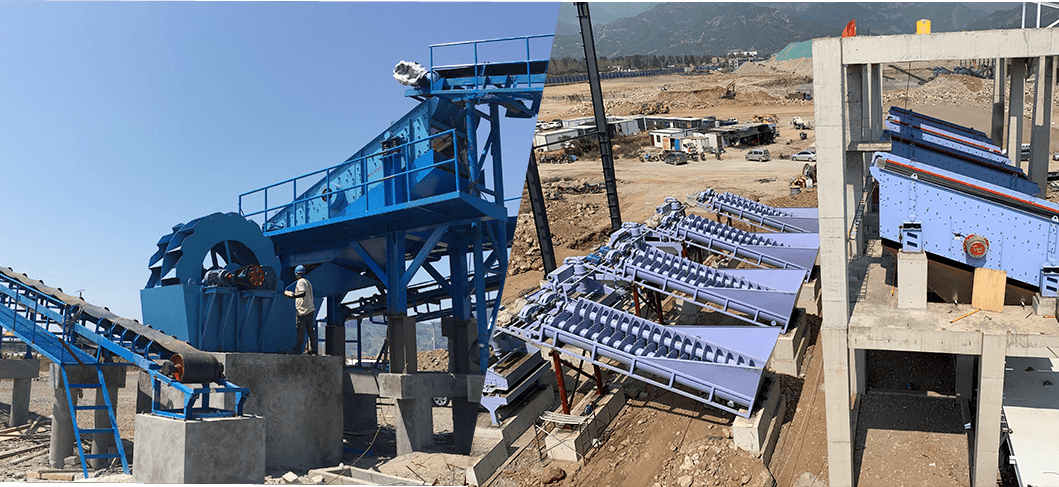

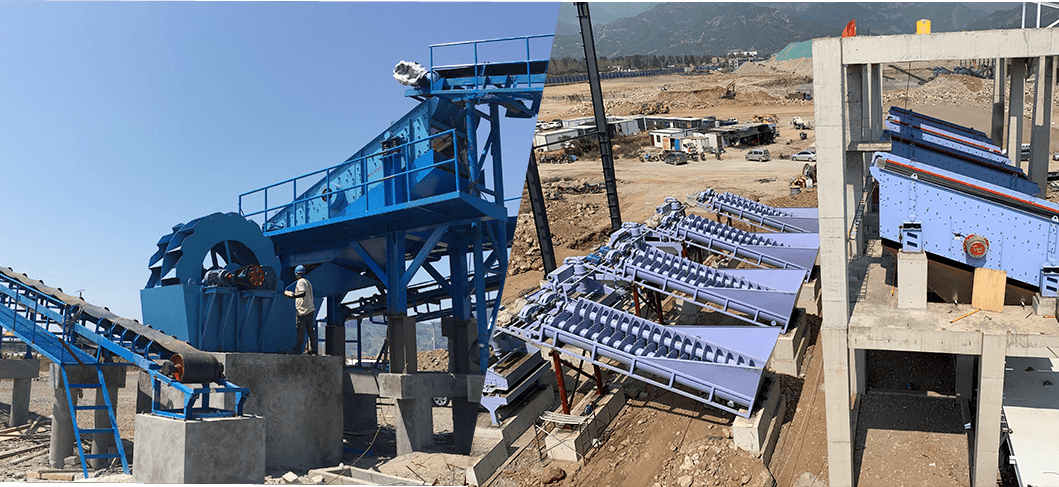

Case

- Features

- Working Principle

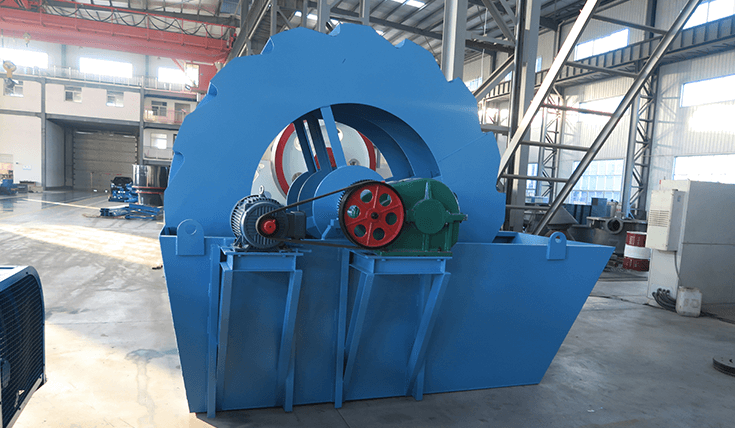

XS Series Sand Washer

1.Simple structure, convenient to repair.

2.High processing capacity and low power consumption.

3.Low wear-parts consumption, low cost.

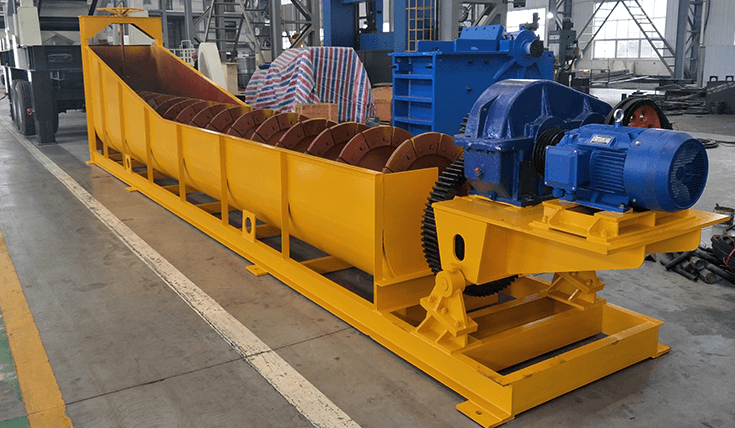

XL series spiral sand washing machine

1, strong processing ability, high washing rate, low power consumption, good sealing

structure, fully enclosed transmission, adjustable jaws.

2, the product is efficient, durable, clean, dehydrated, fine-grained products remain stable.

During the operation, the spiral sand washer rotates by the force of the spiral impeller, rotates the impeller and rolls the sand mechanism in the machine body, so that the mechanical sand is broken and milled, and the impurities covering the sandstone surface are eliminated. Destroy the water vapor layer of the coated sand to promote dehydration. At the same time, add water to form a strong water flow, remove foreign matter with less impurities and small specific gravity in time, and discharge from the overflow port to complete the cleaning work, and finally rinse the mechanical sand with water. The rotation of the helical impeller enters the discharge conduit.

The spiral sand washer has a central structure and the spiral blades are mounted on the central shaft. The power of the transmission rotates the central shaft to drive the rotation of the screw and the floating effect of the sand material on the first stage of the can and the screw. Dust and impurities are separated from the sand to achieve drainage and eliminate impurities. When the spiral sand washing machine is working in the field, the main body has an immersion angle, the feeding end is low, the discharge end is high, and the finished product is excluded from the high end.

Delivery Site